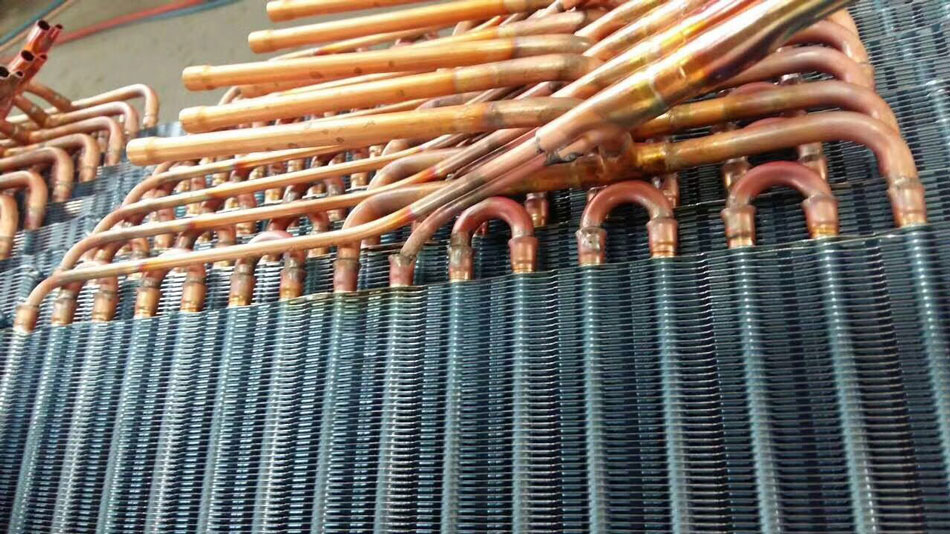

For heat-exchangers, engine radiators, domestic refrigerators, commercial refrigerators, industrial refrigerators, air conditioners, wall boilers, gas boilers, electric home appliances, coils, condensers, evaporators, compressors for cooling, refrigerated cabinets, Heating plants, water, floor heating piping, etc..

Phosphorous copper alloys

| Standard |

Alloy |

Chemical Composition(%) |

Melting Range |

| Solidus |

Liquidus |

| AWS A5.8 |

BCuP-2 |

Cu:Bal. P:6.5-7.5 |

710℃ |

790℃ |

| AWS A5.8 |

BCuP-3 |

Cu:Bal. P:5.7-6.1 Ag:5.0-5.2 |

643℃ |

816℃ |

| AWS A5.8 |

BCuP-5 |

Cu:Bal. P:4.8-5.3 Ag:14.5-15.5 |

643℃ |

800℃ |

| AWS A5.8 |

BCuP-6 |

Cu:Bal. P:6.8-7.5 Ag:1.8-2.2 |

643℃ |

790℃ |

|

BCu86PSn |

Cu:Bal. P:6.5-7.5 Sn:6.5-7.5 |

640℃ |

680℃ |

Aluminum and aluminum alloy welding wire

| Standard |

Alloy |

Chemical Composition(%) |

AWS A5-10

EN ISO18273-S |

ER4043

AlSi5 |

Al:Bal. Si:4.50-5.50 Fe:0.80 Cu:0.30 Mn:0.05 Mg:0.05 Zn:0.10 Ti:0.20 Other:0.15 |

AWS A5-10

EN ISO18273-S |

ER4047

AlSi12 |

Al:Bal. Si:11.0-13.0 Fe:0.60 Cu:0.30 Mn:0.15 Mg:0.10 Zn:0.20 Ti:0.15 Other:0.15 |

Aluminum flux cored brazing wire

| Type |

Composition |

Brazing temp ℃ |

Flux Proportion |

Wire Diameter |

Note |

| Alloy |

Flux |

(wt%) |

(mm) |

| BD812 |

Al88Si12(4047) |

K Cs Al F |

595~625 |

low:10-15%

Standard type:15-25% |

Φ1.2~Φ2.4 |

Aluminum to aluminum brazing |

Aluminium to copper flux cored brazing wire

| Type |

Composition |

Brazing temp ℃ |

Flux Proportion |

Wire Diameter |

Note |

| Alloy |

Flux |

(wt%) |

(mm) |

| BD802 |

1# ZnAl alloy |

Cs Al F 4 |

420-480 |

10-20% |

Φ1.6~Φ2.4 |

Copper to Aluminum brazing |

| BD822 |

2# ZnAl alloy |

420-480 |

| BD815 |

3# ZnAl Alloy |

420-480 |