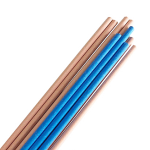

Flux Coated Brazing Rods

A general purpose Flux Coated Rod that combines flux and the brazing filler metal into a single form. It's ideal for everyday repairs of steel, cast iron and copper metals. Can save labor cost. With highly versatile and strong, it's widely used for Oxygen/Acetylene Welding/Brazing and can also be used on galvanized iron, brass, stainless, copper and chrome-plated materials, or any combination of them. Provides strong corrosion resistance. This rod can be used to join similar and also dissimilar metals such as mild steel to galvanized steel, stainless steel to copper, mild steel to stainless, stainless to copper nickel and mild steel to cast iron.