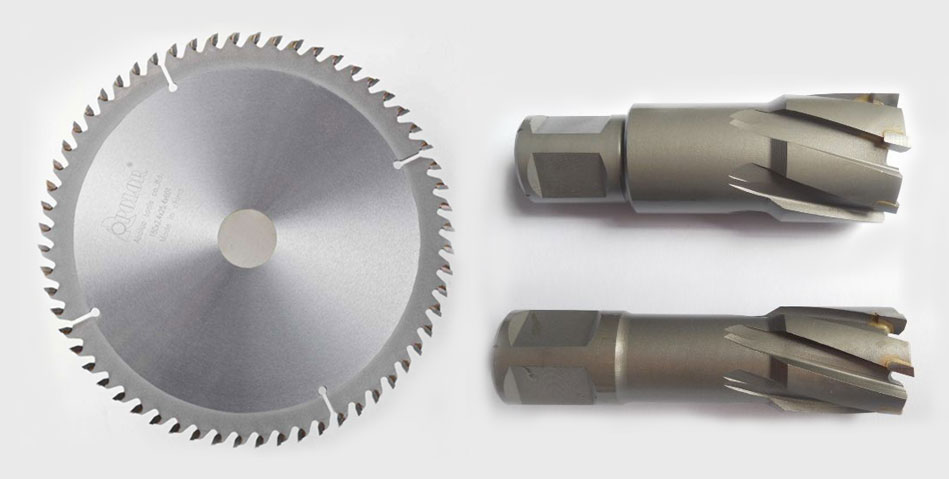

For Diamond tipped tools, tungsten carbide tipped tools, tools for working and cutting of stone, saw blades, crushers, mining and drilling tools, surgical instruments, etc.

Diamond and Carbide Tipped tools

High temperature brazing materials

| Standard | Alloy | Chemical Composition(%) | Melting Range | |

| Solidus | Liquidus | |||

| DIN EN 1044 EN ISO 3677 |

CU105 Cu97Ni3(B) |

Cu: Bal. Ni:2.5-3.5 B: 0.02-0.05 | 1085℃ | 1100℃ |

| / | Cu87MnCo3 | Cu: Bal, Mn:10 Co:3 | 980℃ | 1030℃ |

| / | Cu86MnNi2 | Cu: Bal. Mn:12 Ni: 2 | 960℃ | 990℃ |

| / | Cu85MnNi3 | Cu:Bal. Mn:12, Ni:3 | 960℃ | 990℃ |

| / | Cu67MnNi9 | Cu:Bal. Mn: 24, Ni:9 | 950℃ | 955℃ |

| / | Cu58ZnMnCo2 | Cu:58 Mn: 2 Co:2 Zn: Bal. | 875℃ | 890℃ |

| / | Cu55ZnMn4Ni6 | Cu: 55 Ni: 6 Mn:4 Zn: Bal. | 880℃ | 920℃ |

| / | CuMn38Ni9.5 | Cu:Bal. Ni: 9.5 Mn:38 | 880℃ | 925℃ |

| ISO24373 BS EN14640 |

CuAl8Ni2Fe2Mn2 CuAl8Ni2 |

Cu:Bal. Al:7.0-9.5 Fe:0.5-2.5 Mn:0.5-2.5 Ni:0.5-3.0 Si:0.2 Zn: 0.2 Other:0.4 | 1030℃ | 1050℃ |

| AWS A5.7 BS EN14640 |

ERCuNiAl CuAl9Ni5 |

Cu:Bal. Al:8.5-9.5 Fe:3.0-5.0 Mn:0.60-3.5 Ni:4.0-5.5 Si:0.1 Zn: 0.1 Other:0.5 | 1015℃ | 1045℃ |

| AWS A5.7 BS EN14640 |

ERCuMnNiAl | Cu:Bal. Al:7.0-8.5 Fe:2.0-4.0 Mn:11.0-14.0 Ni:1.5-3.0 Si:0.1 Zn: 0.15 Other:0.5 | 945℃ | 985℃ |

Brass brazing alloys

| Standard | Alloy | Chemical Composition(%) | Melting Range | |

| Solidus | Liquidus | |||

| AWS A5.8 BS EN14640 |

RBCuZn-A CuZn40 |

Cu:59 Sn:0.6 Zn:Bal. Other:0.5 | 886℃ | 901℃ |

| AWS A5.8 BS EN14640 |

RBCuZn-B CuZnNi |

Cu:58 Fe:0.7 Si:0.1 Mn:0.5 Ni:0.5 Sn:1.0 Zn:Bal. Other:0.5 | 866℃ | 882℃ |

| AWS A5.8 | RBCuZn-C | Cu:58 Fe:0.7 Si:01 Mn:0.5 Sn:1.0 Zn:Bal. Other:0.5 | 866℃ | 888℃ |

| AWS A5.8 BS EN14640 |

RBCuZn-D CuZn40Ni10 |

Cu:48 Si:0.1 Ni:10.0 P: Max0.25 Zn:Bal. Other:0.5 | 921℃ | 935℃ |

| HS221 | Cu:59 Sn:1.0 Si:0.2 Zn:Bal. Other:0.5 | 875℃ | 890℃ | |

| Cu48ZnNi9Ag | Cu:48 Zn:Bal. Ag:1 Ni:9 Si:0.2 Other:0.5 | 890℃ | 920℃ | |

High silver brazing alloys

| Standard | Alloy | Chemical Composition(%) | Melting Range | |

| Solidus | Liquidus | |||

| AWS A5.8 | BAg-35 | Ag:34-36 Cu:31-33 Zn:32-34 | 677℃ | 732℃ |

| AWS A5.8 | BAg-5 | Ag:44-46 Cu:29-31 Zn:24-26 | 663℃ | 743℃ |

| AWS A5.8 | BAg-6 | Ag:49-51 Cu:33-35 Zn:14-18 | 688℃ | 714℃ |

| AWS A5.8 | BAg-12 | Ag:29-31 Cu:27-29 Zn:20-22 Cd:20-22 | 600℃ | 690℃ |

| AWS A5.8 | BAg-1 | Ag:44-46 Cu:14-16 Zn:14-16 Cd:23-25 | 595℃ | 630℃ |

| AWS A5.8 | BAg-7 | Ag:55-57 Cu:21-23 Zn:16-18 Sn:4.5-5.5 | 620℃ | 650℃ |

| BAg18CuZnSn | Ag:17.5-18.5 Cu:45-47 Zn:33-35 Sn:1.5-2.5 | 780℃ | 810℃ | |

| BAg30CuZnSn | Ag:29-31 Cu:35-37 Zn:31-33 Sn:1.5-2.5 | 650℃ | 750℃ | |

| BAg40CuZnSn | Ag:39-41 Cu:29-31 Zn:27-29 Sn:1.5-2.5 | 650℃ | 710℃ | |

| BAg40CuZnSn | Ag:44-46 Cu:26-28 Zn:23-27 Sn:2.5-3.5 | 650℃ | 710℃ | |

Flux coated tungsten carbide chips rods

YG(70%) CuNiZn(30%) carbide copper alloy brazing rod

it is mainly used for surfacing welding the oil, mining, coal mining, geology, construction and other industries in some serious wear and tear or artifacts of both cutting.Such as: milling shoes, grinding, centralizer, reamer, drill pipe joints, hydraulic cutter, scraper, plough planer knives, core bit, piling drill, twist drill, etc.

| Grade | Size(mm) | Scrap size(mm) | Color |

| YD-9.5 | 9.5 | 9.5~6.5 | dark green |

| YD-8 | 8.0 | 8.0~6.5 | dark blue |

| YD-6.5 | 6.5 | 6.5~5.0 | red |

| YD-5 | 5.0 | 5.0~3.0 | yellow |

| YD-3 | 3.0 | 3.0~2.0 | pink |

| YD-10mesh | 10mesh | 10~18mesh | light green |

| YD-18mesh | 18mesh | 18~30mesh | light green |

| YD-30mesh | 30mesh | 30~50mesh | light yellow |

ROD SIZE: 12*280mm 16*450mm 22*450mm